Balcony glazing with added value

Corrosion protection is also optimised“Our balcony systems have proven themselves as an incentive for attracting tenants. As such, our flats were all full in times when other associations reported vacancy rates of up to ten percent,” reports Marion Dawurske, board member and managing director at Berliner Wohnungsgenossenschaft Altglienicke. One major reason for this could be the luxurious balconies, which each newly built flat is now furnished with, and which the old stock was gradually upgraded to include.

Dawurske expands on the special features on a visit to the construction site of the newly built project in Berlin-Adlershof, and it soon becomes clear that not all balconies are the same. “The tenants use our balconies like a second living room – they even put leather furniture and televisions on them.” This is entirely safe, as the balconies are clad in sliding glass elements that protect them from wind and rain and transform the outdoor seating into a virtual winter garden. The association’s balconies, measuring up to twelve square metres, are a welcome expansion to the living space.

Score points with top-quality balconies

Marion Dawurske has quite an unusual approach to renovating existing housing, as all new balcony systems were constructed without any modernisation tax, i.e. without any increase in rent. “We donated them, in a sense. Being an association, we don’t need to generate any gains,” she says. But this business doesn’t take any losses. On the contrary, as a director, she makes razor-sharp calculations and says of herself: “I am the type who either does something right, or not at all.” Modernisations existed before her time in office, but unfortunately were evidently of bad quality. Many balconies had to be demolished again after only eight years and as such their use was highly restricted. “The association’s members were very unhappy,” she recalls.

Marion Dawurske decided on balconies from Balco. The pilot project involved 400 glazed balconies on 11-storey WBS 70 prefabricated buildings from the GDR era. “We had no idea that the enthusiasm for the luxurious outdoor seating would catch on with the other tenants and we were practically forced to modernise the other flats in the same way.” New flats like those in Berlin-Adlershof are also built exclusively using the Balco system,” she says. The housing association never regretted this, as the flats are often fully rented out long before the reference date.

Glazing extends life span

One feature of the Balco balconies is the sliding glazing. This offers users greater convenience, as they can close the balcony when needed and thus protect it from the elements. This protection not only benefits the building itself, but also the entire balcony structure, including the concrete cantilever panels – an advantage that is also considered valuable for redevelopment properties.

Ralf Schmidt, Head of Project Management for Germany explains: “Aging balconies need to be renovated, especially the balcony slab. “Concrete corrosion”, i.e. the corrosion of the reinforcement in the reinforced concrete ceiling of the balcony, generally requires extensive and costly repairs. This is caused by water penetrating the ever-present hairline or settlement cracks and can reach deeper areas of the floor panels.” As the complete glazing protects the concrete slab from permanent seepages and the corrosion that results, the concrete restoration can be completed more cost-effectively. All in all, despite the higher acquisition costs, the result is a cost benefit which can be demonstrated mathematically. Above all, the customer saves on the otherwise costly coating and re-profiling of the concrete slab. Furthermore, the life span is significantly extended, reducing future maintenance and renovation costs.

Marion Dawurske estimates a life span of up to 50 years until the next general renovation is due and substantiates this as follows: “The first Balco balconies were installed 17 years ago. Since then, over 1,600 have been constructed. Previously, regular maintenance work was never required – we just didn’t need them.” As a result, no maintenance contracts were concluded either. The system is robust and can be easily cleaned by the user. It was very seldom that castors needed to be changed, the only cause being improper use. “From our own experience, we can say that the system is virtually maintenance-free,” says the director in praise of it.

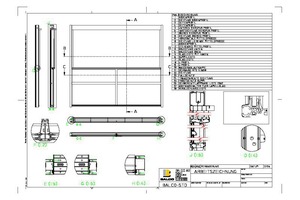

Complete system with integrated drainage

Balco offers several glazing systems. The Villa system is a one-storey version, in which the sliding elements can be opened downwards to fully open up the space. The glazing connects a closed terrace area with an open one and therefore lies within the required balustrade. This construction is popular for roof terraces and penthouse flats. The twin system includes a fixed balustrade, which can be made of glass, HPL or other facing materials. The sliding window elements are arranged above it. Fixed walls are also possible and are generally used for lateral panels. The windows can be slid into any position and opened in any position. If they are slid to the side in tandem, then the entire glazing can be opened out. Each panel has a lever, making it extremely simple to operate, and cleaning is a speedy task. An integrated brush sealing prevents draughts. System Access is a special glazing system for balustrades. Besides additional weather and heat protection for the building, it also offers a higher slip resistance on the corridors – an aspect which is advantageous for retirement homes and public buildings, amongst other constructions. The windows can be slid from side to side either electrically or by hand. This system fulfils current fire protection standards, as the windows open automatically in the case of fire or smoke.

The glazing systems primarily consist of an aluminium structure which is positioned in front of or on top of the reinforced concrete floor panel as a pre-fabricated component. A regulated drainage system takes up the rainwater as far as possible and conducts it between the columns and posts down to the ground. The water is collected in the handrail and in the guide rails of the sliding elements, i.e. in the glazing construction; the water is guided via the profiles and posts of the entire construction. “This way, the rainwater does not run off via the balustrade elements or the balcony panel and is therefore kept for the most part far away from the facade,” explains project manager Dirk Höhne.

The joint is closed between the glazing and the balcony panel with an “adjustable profile,” which can be adjusted to the gap width. If particularly large quantities of water enter the balcony, this profile practically functions as emergency drainage, as the water can flow out through the existing holes.

Easily adaptable to country standards

The pre-fabricated basic construction as well as the complete portfolio can be adapted to any style of architecture and in principle can thus be used in all countries. There may be differences in the construction concerning the holding system for the glazing and the required structural attachments, which generally result from differing standards and structural conditions in various countries. “In Sweden, for example, suspended balconies, i.e. unsupported ones, are preferred. In Germany this is very rarely in demand. The typical German balcony door sits on two or four supports and a base. The standards permit special attachment solutions which is why we work with Hilti and Würth when it comes to attachment technology in Germany,” says Dirk Höhne.

Country-specific differences primarily play a role in the execution: “In Germany, we can very rarely work with clear glass in the balustrade area, because this is regarded as invading the private sphere. Matt-white or coloured glass is preferred, as are opaque facing panels. Colour is an important element of the facade construction. The Scandinavians on the other hand, love a clear view with plenty of light exposure,” says Ralf Schmidt.

Metal engineering company sought for installation

The Balco headquarters is located in Växjö, in the Småland region of Sweden. The 275 employees generated around 80 million euros in sales for 2015. The company has branches in Denmark, Norway, Finland, the Netherlands, Great Britain and Germany. The Swiss market is under development, as is the Austrian market. Production takes place predominantly in the company’s own plants in Sweden and Poland, where purchased parts include reinforced concrete panels. When it comes to installation, there are existing long-term partnerships with special installation companies in individual countries. The logistics are also managed using experienced shipping companies.

The company designs its balcony systems exclusively for apartment buildings of around 20 units and up. “This is economically advantageous for both us and our customers,” explains Ralf Schmidt. The ratio of new constructions to renovated buildings is around 30 to 70 percent in Germany, which is above all due to the increasingly smaller proportion of new constructions in apartment buildings and communal housing. Balco Deutschland has its headquarters in Berlin and has its own construction department. Priority regions such as Bavaria, North Rhine-Westphalia, Berlin and the new federal states are supervised by field sales representatives. The company seeks to cooperate with additional metal engineering companies in order to further expand its presence on the German market.